Ariel Mt Zip Le And

Expand the arial.zip le and move the folders inside it to the required places in your local texmf folder hierarchy.Ariel & Shawdon wanted to be married somewhere beautiful, somewhere surreal and in their search they came across Mt.

Ariel Mt Download Or Make

I also thought Arial was a Base 14 font and so will not get em.ARIEL 3LT DUAL MT - PW (2705-10-70) by Quorum. Width: 10.50.Ariel and Shawdon are two of the sweetest happiest souls I have ever met and Ariel’s smile is infectious! The entire day, they were laughing, smiling, hugging and just enjoying every moment of their wedding day. Download or make copies of the Arial fonts.

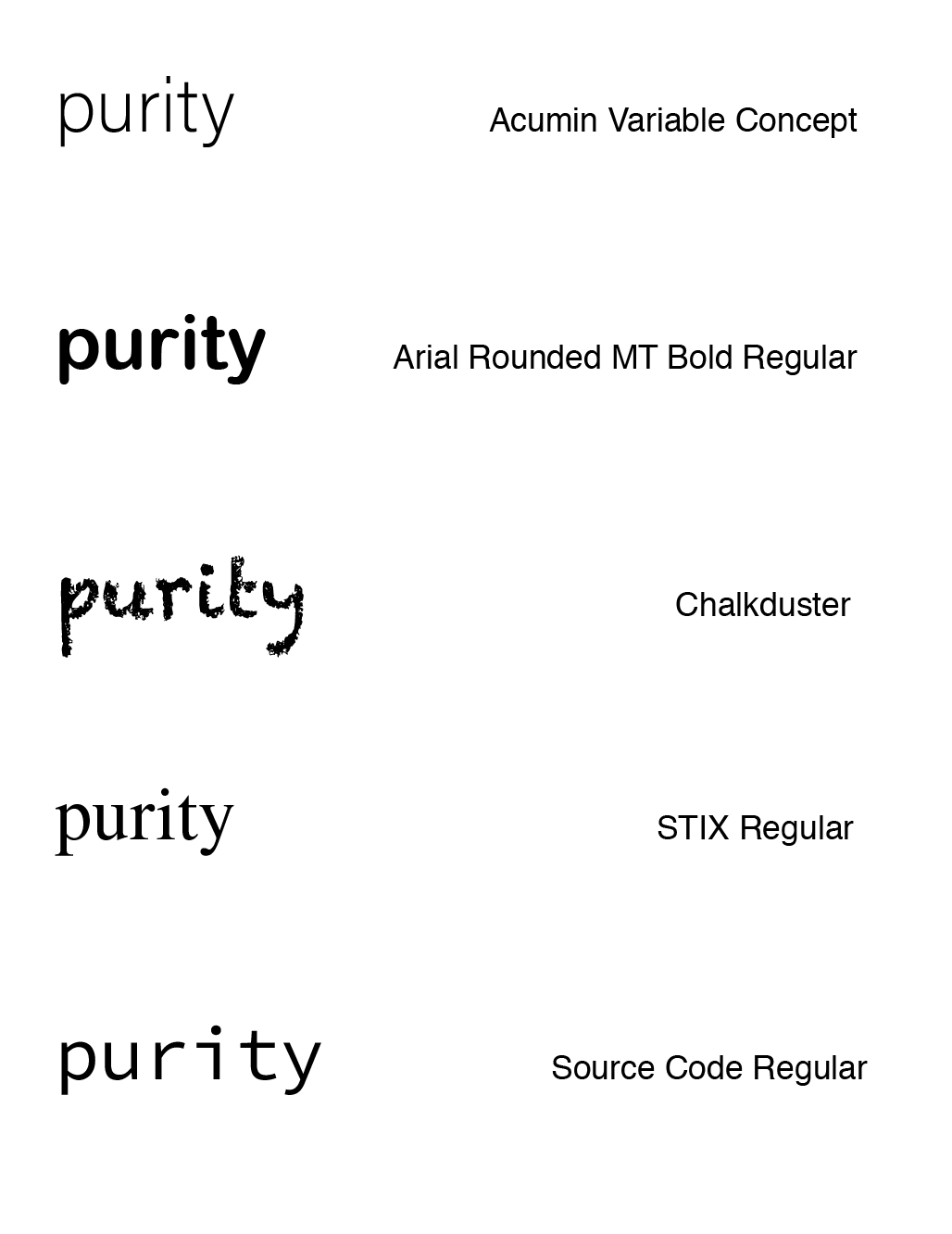

Once you are pleased with the settings for that section you can click save. Your selections will remain as you look for another font for another section of this preview. Another sub heading in Arial Rounded MT Bold.

A history major minoring in math, he graduated from Baldwin-Wallace College in 1949 with a teaching certificate. Jim Buchwald grew up in Cleveland and went off to college in nearby Berea, Ohio. There is a blockquote next to it. You may want to make that stand out. Preview Your Fonts Your headline is in Arial Rounded MT Bold This is a sub heading in Arial Rounded MT Bold.This paragraph is in Arial Rounded MT Bold. Keep reading for how to use the buttons to the left.

Maureen worked to support them until Jim earned his mechanical engineering degree in 1954. Jim worked for more than a year as a bank teller and then as a clerk at the Cleveland Tank Plant, operated by General Motors, to save up money to attend the Case Institute of Technology (now Case Western Reserve University) in the fall of 1951. Fascinated with machinery since he was a little boy, Jim realized he wanted to become an engineer. By the summer after his failed attempt at teaching, the two were married and Jim had a vision for what he truly wanted to do with his life. He returned to his parents’ home defeated but not completely demoralized: in Vienna he had met eighteen-year-old Maureen Hunter.

Ariel Mt Free Piston Engine

The young family settled into Mount Vernon, a charming town on the Kokosing River, an hour northeast of Columbus.Although Cooper decided to scrap its plans for a free piston engine, Jim developed a mentorship with the project’s lead engineer, Bob Ramsey. Maureen gave birth to their first child, Karen, just weeks after Jim had graduated from Case Institute. The job came just in time.

Later, when he started building compressors, Jim would recognize that his time with the people on the shop floor had provided the foundational values for the company he created. At the same time Jim was getting an education on how things were done in compressor manufacturing, he also began to notice certain design and manufacturing processes that could be improved, but were not, because of poor understanding by management. Jim immersed himself in this new field, meeting with machinists, patternmakers, and foundrymen to understand the best way to design and build compressors. Both Jim and Maureen saw it as a wonderful opportunity for Jim to take on greater responsibility. The job was to design compressors to complement their line of medium-speed gas engines.

Jim’s proposal was rejected, and perhaps more significant, Jim was passed over for the position of chief engineer. About five years into his work at White Superior, Jim presented his boss with a plan for an 1,800-rpm compressor that matched the large diesel engines that Cummins Engine Company, a competitor courting White Superior for merger, was marketing. “I knew my way around the plant, I knew machinists and enjoyed learning from them, and almost everything that I tried to do was based on experiences in companies that didn’t always do things as well as they could, and should.”The line of compressors he designed for White Superior was a valuable addition to its medium-engine market.

They both hailed from Jim’s former employers: Doane was a fellow engineer who still worked for Cooper-Bessemer, while Woodman was in sales at White Superior. In two men, Jim Doane and George Woodman, Jim found the partners he needed to strike out on his own. For the next two years, Jim worked on the Enterprise Delaval design contract, but also had sufficient time to design the small high-speed compressor that would launch Ariel. Jim and Maureen moved their family back to Mount Vernon, Ohio, in December of 1965.While the Buchwalds lived in Springfield, Ohio, the family grew to include two sons, Philip, born in 1956, and Kurt, born in 1965, a year before the family returned to Mount Vernon. The job would require a lot of travel, especially to Oakland, California, where Enterprise’s plant was located, but it also required close collaboration with Ramsey, who still lived in Mount Vernon, Ohio. Once again Bob Ramsey provided the next step for Jim in 1965, when he subcontracted with Jim for work he was doing to design a line of compressors for Delaval Turbine to match the drivers of newly acquired Enterprise Engine.

The following year, Jim Buchwald and Jim Doane set up a small machine shop in the Buchwald family basement to build a prototype they planned to use to attract investors in the business since the partners had so little money of their own.“The basement walls were rough-hewn stone blocks and it was a really gloomy place,” recalls Karen. “He had a lot of experience in the manufacturing of capital goods, he had an intense capacity to analyze problems, and he had the determination to solve them.” The company was incorporated on April 27, 1966. “Jim is a very intelligent person,” says Maureen. And Jim had Maureen’s confidence as well.

By 1968, the partners were ready to test the compressor, culminating in a ten-hour, fullspeed test on June 29. With the exception of the cylinders, which were too heavy, each part was brought back to the Buchwalds’ basement for assembly after it was machined. They spent most of 1967 machining parts for the prototype while all three partners continued to work full time. They rented a third of the facility for just $30 per month, though it was dirty and smelly—it was instantly christened the Chicken Pluckin’ Factory—and did not have a bathroom. By August of that year, the project had partially outgrown the basement, thanks to the purchase of a 1907 Lucas horizontal boring mill, which was much too long and heavy to be taken down the basement stairs.Jim Buchwald found a former turkey processing operation in Bellville, Ohio, about twenty miles north of Mount Vernon. “They were real secretive about this, and as I think about it now and realize how young my dad was, I’m sure he was having a lot of fun with the whole secret enterprise thing they had going on.” The three partners financed the building of the prototype with $10,500— $5,000 from Jim Buchwald, $3,000 from Jim Doane, and $2,500 from George Woodman—each paying out 10 percent of their share monthly.(Upon completion of the design, Jim Buchwald received an additional $1,000 worth of company stock.) They purchased a lathe and a rotary table outfitted with a vertical drill so they could machine some of the prototype’s parts themselves instead of sending the castings out to a job shop.

“My dad always enjoyed when he went out to dinner with ‘Georgie,’ as he called him, because then he didn’t have to worry about where people should sit or figuring out the tip: George always took care of that. I’ll sell it for you.’ I think sometimes that’s what a person needs—to be told they can do it—and that’s what George did for my dad.”Woodman, a quiet and genial man, had warm friendships with many people in the industry as well as a polished social style that appealed to Buchwald. “I think that George said repeatedly to him, ‘Jim, you’re a brilliant designer you should do this. “Without George’s encouragement he might not have done it,” says Karen.

0 kommentar(er)

0 kommentar(er)